Swage Nipple and Bull Plugs Manufacturers, Suppliers, Stockist – MSS SP-95, BS 3799 – ASTM A105, A182 F304, F316, F304L, F316L, and A182 F5, F9, F11, F22, F91

- Size: from 1/8” NPS TO 8” NPS, DN8 TO DN200, Thread: NPT, NPSC, BSPT, BSPP, Type: Male and Female

- Types of Swages – Swage Nipples, Concentric Swage Nipple, Eccentric Swage Nipple, NPT/BSPT Threaded Swage Nipples, High Pressure Swage Nipples, Stainless Steel Swage Nipples, Carbon Steel Swage Nipples, Alloy Steel Swage Nipples, Duplex & Super Duplex Swage Nipples or Swage

Swage Nipple is a kind of pipe reducer product that is used to connect pipes in different dimensions. It has various end forms and TBE (threaded both end) type is very prevalent among concentric swage nipples. Metallica is a well known manufacturer and supplier of Swage Nipples, Bull Plugs, Concentric Swage Nipple, Eccentric Swage Nipple, and NPT/BSPT Threaded Swage Nipples for the clients from oil and gas, petrochemicals, railway, construction and other industries. Swage nipples may be made to special dimensions, size, shape, tolerances, or of other wrought material by agreement between the manufacturer and the purchaser. We can produce swage nipples in size range of 1/2″ to 8″. The most common and materials include ASTM A105, ASTM A182 F304, F316, F304L, F316L, and A182 F5/F9/F11/F22/F91. In nickel alloys we manufacturing swage nipples in various grades such as Alloy 200, 201, 400, K500, 600, 625, 800H/HT, 825, X-750, C276, Hastelloy B & C22.

Forged Socket Weld & Threaded Pipe Fittings Manufacturing Standards

- ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

- ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

- ASME B16.11 – Socket Welding and Threaded Forged Fittings

- MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

- MSS SP-95 – Swage (d) Nipples and Bull Plugs

- BS3799 – Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry

- MSS SP-83 – Socket Welding and Threaded Steel Pipe Unions

- MSS SP-97 – Integrally Reinforced Forged Branch Outlet Fittings –Socket Welding, Threaded, and Buttwelding Ends

Socket weld and threaded fittings are generally used for small size pipes and piping systems (generally below 4 inches in diameter for Class 3000, and below 2 inches for fittings in class 6000 and 9000). Forged pipe fittings are manufactured by forging, followed by heat treatment and machining solid steel as per the dimensional standards. For bigger size piping systems buttweld pipe fittings produced as per ASME B16.9 are used.

Production Range of Swage Nipples

| Product | Swage Nipples (Concentric/Eccentric) |

| Connection | Threaded, Plain End, Butt Weld |

| Size | 1/8” NPS TO 8” NPS, DN8 TO DN200 |

| Thickness | Sch 10s, Sch 20, STD, Sch 40, XS, Sch 80, SCH 160 |

| Process method | Forged, CNC Machined |

| Standards: | MSS SP 95, BS 3799 |

| Certification | EN 10204 3.1 |

- Thread: NPT, NPSC, BSPT, BSPP

- Type: Concentric Swage and Eccentric Swage Fittings

- Raw Materials: A106 Gr. B Seamless Pipes, A105/A105N Bars, A182 304/304L Bars, A182 316/316L Bars, A312 304/304L Seamless Pipes, Duplex Seamless Pipes, A312 316/316L Seamless Pipes, A350-LF2, Alloy Steel Seamless Pipes/Bars

- Ends: Beveled, Square Cut (for socket-weld)

Types of Connection Ends for Swage Nipples

| BBE = Bevel both ends | TBE = Thread both ends |

| PBE = Plain both ends | GBE = Grooved both ends |

| TXG = Thread by groove | TXB = Thread by bevel |

| PXG = Plain by groove | BXT = Bevel by thread |

| TLE = Thread large end | PLE = Plain large end |

| BLE= Bevel large end | PSE = Plain small end |

| BSE= Bevel small end | TSE = Thread small end |

Swage Nipple Materials & Grades

| Carbon Steel | ASTM A105/N, ASTM A350LF2, LF3, LF6 |

| Duplex | 2205(F51/60), 2507(F53) |

| Chrome Moly | SA182, F1, F5, F5a, F9, F9l, F11, F12, F22 |

| Stainless Steel | 304/L/H, 316/L/H, 310, 317L, 321/H, 347/H, 410, 416, 420, 17-4, 440, Alloy 20 |

| Nickel Alloys | 200, 201, 400, K500, 600, 625, 800H/HT, 825, X-750, C276, Hastelloy B & C22 |

Dimensions of Concentric & Eccentric Swage Nipples MSS SP-95, BS 3799

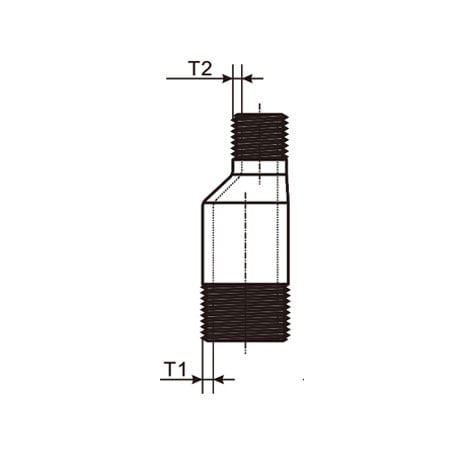

Concentric Swage Nipple (TBE) Drawing

Concentric Swage Nipple (PBE) Drawing

Concentric Swage Nipple (BBE) Drawing

Eccentric Swage Nipple (TBE) Drawing

Eccentric Swage Nipple (PBE) Drawing

Eccentric Swage Nipple (BBE) Drawing

| Nom. | Outside Diameter | End | Wall Thickness | ||||||||

| Pipe | Large | Small | To | T1 | T2 | ||||||

| Size | End | End | End | Sch40 | Sch80 | Sch160 | XXS | Sch40 | Sch80 | Sch160 | XXS |

| (NPS) | D1 | D2 | “A” | (STD) | (XS) | (STD) | (XS) | ||||

| 1/4″×1/8″ | 13.7 | 10.3 | 57 | 2.2 | 3 | 3.7 | 6.1 | 1.7 | 2.4 | ||

| 3/8″×1/8″ | 17.1 | 10.3 | 64 | 2.3 | 3.2 | 4 | 6.4 | 1.7 | 2.4 | ||

| 3/8″×1/4″ | 17.1 | 13.7 | 64 | 2.3 | 3.2 | 4 | 6.4 | 2.2 | 3 | ||

| 1/2″×1/8″ | 21.3 | 10.3 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 1.7 | 2.4 | ||

| 1/2″×1/4″ | 21.3 | 13.7 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.2 | 3 | ||

| 1/2″×3/8″ | 21.3 | 17.1 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.3 | 3.2 | ||

| 3/4″×1/8″ | 26.7 | 10.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 1.7 | 2.4 | ||

| 3/4″×1/4″ | 26.7 | 13.7 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.2 | 3 | ||

| 3/4″×3/8″ | 26.7 | 17.1 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.3 | 3.2 | ||

| 3/4″×1/2″ | 26.7 | 21.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1″×1/8″ | 33.4 | 10.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 1.7 | 2.4 | ||

| 1″×1/4″ | 33.4 | 13.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.2 | 3 | ||

| 1″×3/8″ | 33.4 | 17.1 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.3 | 3.2 | ||

| 1″×1/2″ | 33.4 | 21.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1″×3/4″ | 33.4 | 26.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4″×1/8″ | 42.2 | 10.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 1.7 | 2.4 | ||

| 1-1/4″×1/4″ | 42.2 | 13.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.2 | 3 | ||

| 1-1/4″×3/8″ | 42.2 | 17.1 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.3 | 3.2 | ||

| 1-1/4″×1/2″ | 42.2 | 21.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/4″×3/4″ | 42.2 | 26.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4″×1″ | 42.2 | 33.4 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2″×1/8″ | 48.3 | 10.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 1.7 | 2.4 | ||

| 1-1/2″×1/4″ | 48.3 | 13.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.2 | 3 | ||

| 1-1/2″×3/8″ | 48.3 | 17.1 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.3 | 3.2 | ||

| 1-1/2″×1/2″ | 48.3 | 21.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1.1/2″×3/4″ | 48.3 | 26.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/2″×1″ | 48.3 | 33.4 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2″×1-1/4″ | 48.3 | 42.2 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2″×1/8″ | 60.3 | 10.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 1.7 | 2.4 | ||

| 2″×1/4″ | 60.3 | 13.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.2 | 3 | ||

| 2″×3/8″ | 60.3 | 17.1 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.3 | 3.2 | ||

| 2″×1/2″ | 60.3 | 21.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 2″×3/4″ | 60.3 | 26.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 2″×1″ | 60.3 | 33.4 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.4 | 4.5 | 6.4 | 9.1 |

| 2″×1-1/4″ | 60.3 | 42.2 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2″×1-1/2″ | 60.3 | 48.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.7 | 5.1 | 7.1 | 10.2 |

| 2-1/2″×1/8″ | 73 | 10.3 | 178 | 5.2 | 7 | 9.5 | 14 | 1.7 | 2.4 | ||

| 2-1/2″×1/4″ | 73 | 13.7 | 178 | 5.2 | 7 | 9.5 | 14 | 2.2 | 3 | ||

| 2-1/2″×3/8″ | 73 | 17.1 | 178 | 5.2 | 7 | 9.5 | 14 | 2.3 | 3.2 | ||

| 2-1/2″×1/2″ | 73 | 21.3 | 178 | 5.2 | 7 | 9.5 | 14 | 2.8 | 3.7 | 4.8 | 7.5 |

| 2-1/2″×3/4″ | 73 | 26.7 | 178 | 5.2 | 7 | 9.5 | 14 | 2.9 | 3.9 | 5.6 | 7.8 |

| 2-1/2″×1″ | 73 | 33.4 | 178 | 5.2 | 7 | 9.5 | 14 | 3.4 | 4.5 | 6.4 | 9.1 |

| 2-1/2″×1-1/4″ | 73 | 42.2 | 178 | 5.2 | 7 | 9.5 | 14 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2-1/2″×1-1/2″ | 73 | 48.3 | 178 | 5.2 | 7 | 9.5 | 14 | 3.7 | 5.1 | 7.1 | 10.2 |

| 2-1/2″×2″ | 73 | 60.3 | 178 | 5.2 | 7 | 9.5 | 14 | 3.9 | 5.5 | 8.7 | 11.1 |

| 3″×1/8″ | 88.9 | 10.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 1.7 | 2.4 | 3.2 | 4.8 |

| 3″×1/4″ | 88.9 | 13.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.2 | 3 | 3.7 | 6.1 |

| 3″×3/8″ | 88.9 | 17.1 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.3 | 3.2 | 4 | 6.4 |

| 3″×1/2″ | 88.9 | 21.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 3″×3/4″ | 88.9 | 26.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 3″×1″ | 88.9 | 33.4 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 3″×1-1/4″ | 88.9 | 42.2 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 3″×1-1/2″ | 88.9 | 48.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.7 | 5.1 | 7.1 | 10.2 |

| 3″×2″ | 88.9 | 60.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.9 | 5.5 | 8.7 | 11.1 |

| 3″×2-1/2″ | 88.9 | 73 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 5.2 | 7 | 9.5 | 14 |

| 3-1/2″×1/8″ | 101.6 | 10.3 | 203 | 5.7 | 8.1 | 1.7 | 2.4 | ||||

| 3-1/2″×1/4″ | 101.6 | 13.7 | 203 | 5.7 | 8.1 | 2.2 | 3 | ||||

| 3-1/2″×3/8″ | 101.6 | 17.1 | 203 | 5.7 | 8.1 | 2.3 | 3.2 | ||||

| 3-1/2″×1/2″ | 101.6 | 21.3 | 203 | 5.7 | 8.1 | 2.8 | 3.7 | 4.8 | 7.5 | ||

| 3-1/2″×3/4″ | 101.6 | 26.7 | 203 | 5.7 | 8.1 | 2.9 | 3.9 | 5.6 | 7.8 | ||

| 3-1/2″×1″ | 101.6 | 33.4 | 203 | 5.7 | 8.1 | 3.4 | 4.5 | 6.4 | 9.1 | ||

| 3-1/2″×1-1/4″ | 101.6 | 42.2 | 203 | 5.7 | 8.1 | 3.6 | 4.9 | 6.4 | 9.7 | ||

| 3-1/2″×1-1/2″ | 101.6 | 48.3 | 203 | 5.7 | 8.1 | 3.7 | 5.1 | 7.1 | 10.2 | ||

| 3-1/2″×2″ | 101.6 | 60.3 | 203 | 5.7 | 8.1 | 3.9 | 5.5 | 8.7 | 11.1 | ||

| 3-1/2″×2-1/2″ | 101.6 | 73 | 203 | 5.7 | 8.1 | 5.2 | 7 | 9.5 | 14 | ||

| 3-1/2″×3″ | 101.6 | 88.9 | 203 | 5.7 | 8.1 | 5.5 | 7.6 | 11.1 | 15.2 | ||

| 4″×1/4″ | 114.3 | 13.7 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.2 | 3 | ||

| 4″×3/8″ | 114.3 | 17.1 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.3 | 3.2 | ||

| 4″×1/2″ | 114.3 | 21.3 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 4″×3/4″ | 114.3 | 26.7 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 4″×1″ | 114.3 | 33.4 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.4 | 4.5 | 6.4 | 9.1 |

| 4″×1-1/4″ | 114.3 | 42.2 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.6 | 4.9 | 6.4 | 9.7 |

| 4″×1-1/2″ | 114.3 | 48.3 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.7 | 5.1 | 7.1 | 10.2 |

| 4″×2″ | 114.3 | 60.3 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.9 | 5.5 | 8.7 | 11.1 |

| 4″×2-1/2″ | 114.3 | 73 | 229 | 6 | 8.6 | 13.5 | 17.1 | 5.2 | 7 | 9.5 | 14 |

| 4″×3″ | 114.3 | 88.9 | 229 | 6 | 8.6 | 13.5 | 17.1 | 5.5 | 7.6 | 11.1 | 15.2 |

| 4″×3-1/2″ | 114.3 | 101.6 | 229 | 6 | 8.6 | 13.5 | 17.1 | 5.7 | 8.1 | ||

- Dimensions in Millimeters.

- Wall Thickness: T1 & T2 in accordance with ASME B36.10M

Dimensional Tolerance for Swage Nipples

| Nominal Pipe | Overall Length | Outside diameter at end | Wall Thickness (prior to threading or grooving) | |

| Size(inch) | (mm) | Square Cut Ends(mm) | Other End Connection(mm) | |

| 1/8”to 3/8” | ±1.5 | ±0.4 | ±0.8 | Not less than 87.5% of nominal wall thickness |

| 0.8 | ||||

| 1/2”to 1-1/2” | ±1.5 | ±0.4 | ±1.5 | |

| 0.8 | 0.8 | |||

| 2”to 2-1/2” | ±3.0 | ±0.8 | ±1.5 | |

| 0.8 | ||||

| 3”to 4” | ±3.0 | ±0.8 | ±1.5 | |

Production Range of Bull Plugs

| Product | Bull Plugs |

| Connection | Threaded, Plain End, Butt Weld |

| Size | 1/8” NPS TO 8” NPS, DN8 TO DN200 |

| Thickness | Sch 10s, Sch 20, STD, Sch 40, XS, Sch 80, SCH 160 |

| Process method | Forged, CNC Machined |

| Standards: | MSS SP 95 |

| Certification | EN 10204 3.1 |

- Thread: NPT, NPSC, BSPT, BSPP

- Raw Materials: A106 Gr. B Seamless Pipes, A105/A105N Bars, A182 304/304L Bars, A182 316/316L Bars, A312 304/304L Seamless Pipes, Duplex Seamless Pipes, A312 316/316L Seamless Pipes, A350-LF2, Alloy Steel Seamless Pipes/Bars

- Ends: Beveled, Square Cut (for socket-weld)

Bull Plugs Materials & Grades

| Carbon Steel | ASTM A105/N, ASTM A350LF2, LF3, LF6 |

| Duplex | 2205(F51/60), 2507(F53) |

| Chrome Moly | SA182, F1, F5, F5a, F9, F9l, F11, F12, F22 |

| Stainless Steel | 304/L/H, 316/L/H, 310, 317L, 321/H, 347/H, 410, 416, 420, 17-4, 440, Alloy 20 |

| Nickel Alloys | 200, 201, 400, K500, 600, 625, 800H/HT, 825, X-750, C276, Hastelloy B & C22 |

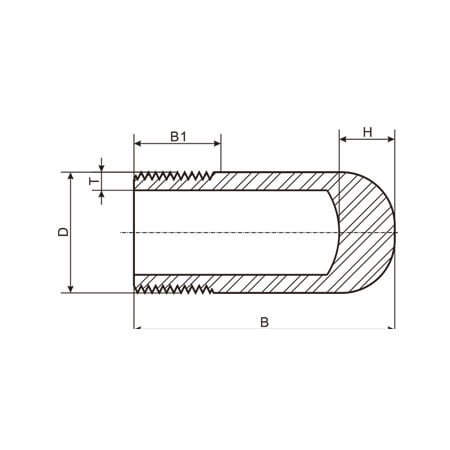

Dimensions of Bull Plugs MSS SP-95

Bull Plugs Drawing

Bull Plugs

| Nom. | D | B | B1 | T(Min.) | H | |||

| Pipe | Sch.40 | Sch.80 | Sch.160 | XXS | ||||

| Size | (STD) | (XS) | ||||||

| 1/8″ | 10.3 | 34 | 9.5 | 1.73 | 2.41 | — | — | 14 |

| 1/4″ | 13.7 | 34 | 11 | 2.24 | 3.02 | — | — | 14 |

| 3/8″ | 17.1 | 57 | 12.5 | 2.31 | 3.2 | — | — | 14 |

| 1/2″ | 21.3 | 64 | 14.5 | 2.77 | 3.73 | 4.78 | 7.47 | 14 |

| 3/4″ | 26.7 | 70 | 16 | 2.87 | 3.91 | 5.56 | 7.82 | 18 |

| 1″ | 33.4 | 76 | 19 | 3.38 | 4.56 | 6.35 | 9.09 | 18 |

| 1-1/4″ | 42.2 | 83 | 20.5 | 3.56 | 4.85 | 6.35 | 9.7 | 18 |

| 1-1/2″ | 48.3 | 89 | 20.5 | 3.68 | 5.05 | 7.14 | 10.15 | 18 |

| 2″ | 60.3 | 102 | 22 | 3.91 | 5.54 | 8.74 | 11.07 | 20 |

| 2-1/2″ | 73 | 127 | 27 | 5.16 | 7.01 | 9.53 | 14.02 | 20 |

| 3″ | 88.9 | 152 | 28.5 | 5.49 | 7.6 | 11.13 | 15.24 | 20 |

| 4″ | 114.3 | 178 | 32 | 6.35 | 8.08 | 13.49 | 17.12 | 20 |

- Dimensions in Millimeters.

- Thread in accordance with ASME B1.20.1

- Wall thickness(T Min.)in accordance with ASME B36.10M.