Production Range of Lug Nut Union

| Product | Lug Nut Union |

| Connection | Socket Weld / Threaded |

| Size | 1/8″ NPS TO 4″ NPS |

| Pressure Rating | 3000LB, 6000LB, 9000LB (SCH80/XS,SCH160,XXS) |

| Process method | Forged, CNC Machined |

| Standards: | ASME B16.11-(SOCKET DIMENSIONS ONLY), ASME B1.20.1-(NPT) |

| Certification | EN 10204 3.1 |

- Thread: NPT, NPSC, BSPT, BSPP, Type: Male and Female

- MS SP-83 contains dimensionals, finish, tolerances, testing, marking, material, and minimum performance requirements for forged carbon and stainless steel pipe unions, socket welding and threaded ends.

Lug Nut Union Dimensions

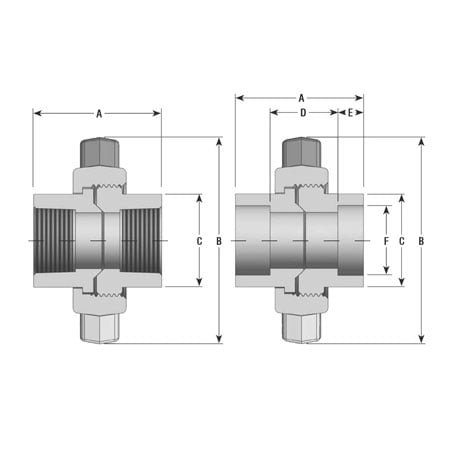

Lug Nut Union Drawing

| CLASS 3000 | ||||||||||

| PIPE SIZE | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.875 | 1.984 | 2.297 | 2.891 | 2.906 | 3.031 | 3.484 | 4.063 | 4.484 | 8.031 |

| B | 2.563 | 3 | 3.625 | 4.25 | 5 | 5.625 | 6.375 | 7.188 | 8 | 10.359 |

| C | 1.031 | 1.031 | 1.484 | 1.813 | 2.188 | 2.469 | 3.031 | 3.656 | 4.406 | 5.453 |

| D | 1.125 | 1.125 | 1.297 | 1.891 | 1.904 | 2.031 | 2.234 | 2.813 | 3.234 | 6.531 |

| Emin | 0.375 | 0.375 | 0.5 | 0.5 | 0.5 | 0.5 | 0.625 | 0.625 | 0.625 | 0.75 |

| F | 0.69 | 0.855 | 1.065 | 1.33 | 1.675 | 1.915 | 2.406 | 2.906 | 3.535 | 4.545 |

| Weight(LBS) | 0.59 | 0.91 | 3.12 | 2.28 | 3.48 | 4.66 | 7.07 | 11.4 | 15.42 | — |

| CLASS 6000 | ||||||||||

| PIPE SIZE | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | — | 2.375 | 2.578 | 2.89 | 3.125 | 3.578 | 4.141 | — | — | — |

| B | — | 3.625 | 4.25 | 5 | 5.625 | 6.375 | 7.188 | — | — | — |

| C | — | 1.469 | 1.797 | 2.172 | 2.563 | 3.031 | 3.688 | — | — | — |

| D | — | 1.625 | 1.578 | 1.89 | 2.125 | 2.578 | 2.89 | — | — | — |

| E | — | 0.375 | 0.5 | 0.5 | 0.5 | 0.5 | 0.625 | — | — | — |

| F | — | 0.855 | 1.065 | 1.33 | 1.675 | 1.915 | 2.406 | — | — | |

| Weight(LBS) | — | 1.95 | 2.84 | 3.96 | — | 7 | 14.16 | — | — | — |

- Seating characteristics of MSS SP-83 Unions.

- The “B” dimension is the diameter across the lugs of union nut.

- Twin Lug design offered in sizes up to 3/4″ Class 3000 & 1/2″ Class 6000.

- Tri-Lug design offered in sizes from 1″ to Class 3000&3/4″ to 2″ Class 6000.

- Quad-lug design offered in 4″ Class 3000.

MSS SP-83 Socket Welding & Threaded Union Manufacturers, Suppliers – ASTM A105, ASTM A182 F304, F316, F304L, F316L, and A182 F5, F9, F11, F22, F91

- Size: from 1/8″ NPS TO 3″ NPS, Pressure Rating: 3000LB, 6000LB (SCH80/XS,SCH160), Thread: NPT, NPSC, BSPT, BSPP, Type: Male and Female

- Types of Unions – Socket Weld Union, Threaded Union, Male x Female Threaded Union, Socket Weld x Female Threaded Union, Butt Weld Union, Lug Nut Union

Metallica is a well known manufacturer and supplier of MSS SP-83 socket welding and threaded steel pipe unions for the clients from oil and gas, petrochemicals, railway, construction and other industries. We manufacture different size and shapes of unions by closed die forging. Our main products include socket weld fittings and threaded fittings in size range of 1/4″ to 4″ (6mm-100mm), with pressure rating of 2000LBS, 3000LBS, 6000LBS, and 9000LBS. The most common and materials include ASTM A105, ASTM A182 F304, F316, F304L, F316L, and A182 F5/F9/F11/F22/F91. In nickel alloys we manufacturing forged union pipe fittings in various grades such as Alloy 200, 201, 400, K500, 600, 625, 800H/HT, 825, X-750, C276, Hastelloy B & C22.

Forged Socket Weld & Threaded Pipe Fittings Manufacturing Standards

- ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

- ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

- ASME B16.11 – Socket Welding and Threaded Forged Fittings

- MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

- MSS SP-95 – Swage(d) Nipples and Bull Plugs

- BS3799 – Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry

- MSS SP-83 – Socket Welding and Threaded Steel Pipe Unions

Socket weld and threaded fittings are generally used for small size pipes and piping systems (generally below 4 inches in diameter for Class 3000, and below 2 inches for fittings in class 6000 and 9000). Forged pipe fittings are manufactured by forging, followed by heat treatment and machining solid steel as per the dimensional standards. For bigger size piping systems buttweld pipe fittings produced as per ASME B16.9 are used.

Pressure & Temperature Service Rating for Class 3000 Carbon and Stainless Steel Unions Socket Welding & Threaded Ends

| SERVICE | NON一SHOCK WORKING PRESSURE (PSI) | |||

| TEMP | ||||

| DEGREE °F | ASTM A105 Carbon Steel | ASTM A182 F316 Stainless Steel | ASTM A182 F304L F316L Stainless Steel | ASTM A182 F304L Stainless Steel |

| 100 | 3000 | 2915 | 2430 | 2915 |

| 200 | 2735 | 2510 | 2050 | 2430 |

| 300 | 2655 | 2265 | 1835 | 2140 |

| 400 | 2565 | 2080 | 1670 | 1905 |

| 500 | 2425 | 1935 | 1545 | 1770 |

| 600 | 2220 | 1830 | 1460 | 1680 |

| 650 | 2180 | 1800 | 1420 | 1650 |

| 700 | 2155 | 1750 | 1390 | 1630 |

| 750 | 1710 | 1360 | 1610 | |

| 800 | 1680 | 1330 | 1595 | |

| 850 | 1645 | 1300 | 1575 | |

| 900 | 1595 | 1555 | ||

| 950 | 1565 | 1515 | ||

| 1000 | 1470 | 1300 | ||

Socket Weld & Threaded Union Materials & Grades

- Carbon Steel: ASTM/ASME A/SA 105, ASTM/ASME A 350 LF2, LF3

- Alloy Steel: ASTM/ASME A/SA 182 F1, F5, F9, F11, F12, F22, F91

- Stainless Steel: ASTM A 182 F304, F304L, F304H, F316, F316L, F316Ti, F310, F321, F321H, F317, F347, F347H, F904L

- Duplex & Super Duplex Steel: ASTM A182 F44, F45, F51, F53, F55, F60

- Copper Nickel Alloys: UNS C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS C10100, 10200, 10300, 10800, 12000, 12200

- Nickel Alloys: ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS N02200), Nickel 201 (UNS N02201), Monel 400 (UNS N04400), Monel 500 (UNS N05500), Inconel 800 (UNS N08800), Inconel 825 (UNS N08825), Inconel 600 (UNS N06600), Inconel 625 (UNS N06625), Inconel 601 (UNS N06601), Hastelloy C 276 (UNS N10276), Alloy 20 (UNS N08020)