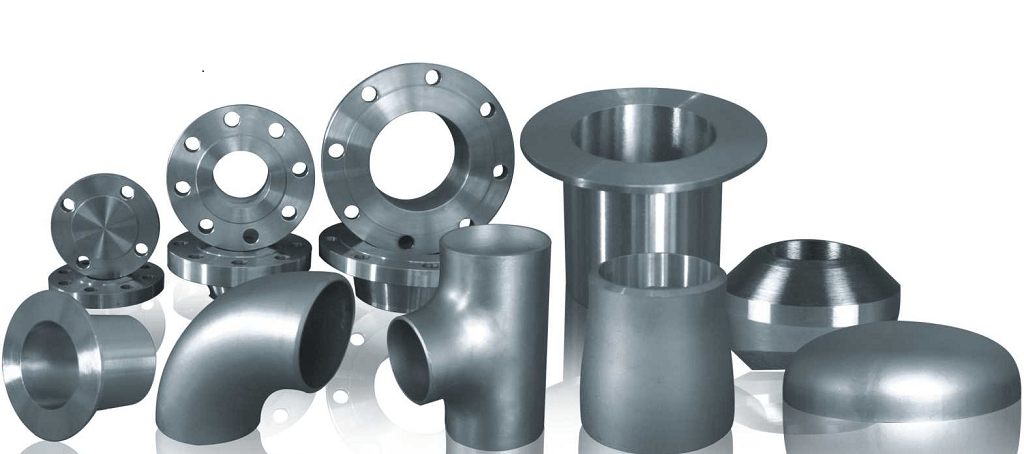

Buttweld Pipe Fittings Manufacturers, Suppliers, Stockists – ASME B16.9, Elbows, Tees, Reducers, Caps, Stub Ends, Crosses, Laterals, Olets, Return Bends

- We have around 30 years experience in manufacturing of buttweld pipe fittings in size ranging from 1/2” to 60”, schedule from Sch5s to SchXXS. Metallica specializes in manufacturing elbows, tee, reducer, caps, crosses, stub ends, etc. conforming to ASME, ANSI, and DIN standard. We also produce custom size pipe fittings made according to drawings from our clients. Common material for buttweld fittings are carbon steel, alloy steel, stainless steel, super austenitic, duplex, super duplex, nickel alloys, titanium, and aluminum etc. Our products are widely used in oil & gas, petrochemical, refineries, power plant, shipbuilding, metallurgy, paper making and other industries.

- A buttweld pipe fitting is a type of pipe fitting, which is designed to be welded on site to connect pipes together. Welding of a buttweld pipe fitting to pipes or other fittings is generally done to allow change in direction of the piping system. Buttweld fittings are generally identified or inquired in nominal pipe sizes with specified pipe schedule. Buttweld fitting’s dimensions and tolerances are defined as per ASME B16.9 standard. All buttweld pipe fittings have beveled ends as per ASME B16.25 standard. This helps create full penetration weld without any extra preparation needed for the buttweld fitting.

- Manufacturing buttweld fittings – A buttweld pipe fitting is made by the process of hot forming that includes bending and forming to shape. The starting material of buttweld fitting is a pipe that is cut to length, heated and molded into specific shapes by means of dies. Heat treatment is also done to remove residual stresses and obtain desired mechanical properties. Sch 10 fittings are also more common in stainless steel buttweld fitting, while SCH 40 is common for carbon steel buttweld fittings.

- Being one of the largest volume buttweld pipe fittings manufacturer and supplier in Mumbai, we can guarantee you the lowest prices. At Metallica Metals, we believe in selling in volume and increasing our customer base across the globe, enabling us to work on low margins. We have an extensive trader network across India, USA, Europe and the Middle East, who buy from us on a regular basis.

- In addition to traders, we have many EPC contractors, companies and end users in various industries as our customers. We are leading buttweld fittings suppliers for various applications ranging from low/medium/high pressure or temperatures.

- ASME 16.9 covers overall dimensions, tolerances, ratings, testing, and markings for factory-made wrought butt-welding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200). The term “wrought” denotes fittings made of seamless or welded pipes, tubing, plates, or forgings. These fittings include long radius elbows, reducing elbows, long radius returns, short radius elbows, short radius 180° returns, 3D elbows, straight tees, straight crosses, reducing tees, reducing crosses, lap joint stub ends, caps, concentric reducers, and eccentric reducers.

ButtWeld Pipe Fittings Manufacturers and Suppliers

Materials-Standards for ASME B16.9 Fittings

| ASTM Standards | Material Specification |

| A234 | Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

| A403 | Wrought Austenitic Stainless Steel Piping Fittings |

| A420 | Wrought Carbon Steel and Alloy Steel for Low Temperature Service |

| A815 | Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Piping Fittings |

| A361 | Wrought Aluminum and Aluminum Alloy Welding Fittings |

| A363 | Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding Fittings |

| A366 | Wrought Nickel and Nickel Alloy Fittings |

Stock and Production Range for Buttweld Fittings

| Product | Buttweld Fittings |

| Type | Seamless or Welded |

| Produce Technology | Seamless, Welding |

| Size | Seamless size from DN15-DN700; Welding size:DN200-DN2000 |

| Thickness | SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160,XS,XXS HIGH THICKNESS TO 80MM |

| Material | – Carbon Steel Buttweld Fittings : ASTM/ASME A234 WPB, WPC – Alloy Steel Buttweld Fittings: ASTM/ASME A234 WP1, WP12, WP11, WP22, WP5, WP91, WP911 – Stainless Steel Buttweld Fittings: ASTM/ASME A403 WP 304/304L, WP 316/316L/316Ti, ASTM/ASME A403 WP 321/321H, ASTM/ASME A403 WP 347/347H – Low-Temperature Buttweld Steel Fittings : ASTM/ASME A420 WPL3/WPL6 – High Performance Buttweld Fittings: ASTM/ASME A860 WPHY 42, 46, 52, 60, 65, 70 |

| Standard | 1) ASME B16.9, ASME B16.25, MSS SP 75, MSS SP 43 2) KS B-1522, KS B-1541 3) JIS 2311, JIS 2312, JIS2313 4) EN10253-1, EN10253-2, EN10253-3, EN10253-4 5) DIN2605-1, DIN2605-2 6) BS1640-1, BS1640-2, BS1640-3, BS1640-4, BS1965-1 7) GOST 17375, GOST 17376, GOST 17378, GOST 17379 |

| Face | Coatings: Special Coating i.e. Cement Mortar Lining, FBE Coating, Galvanized (Hot Dipped Electro-Plating) etc. can be provided |

| Inspection | Chemical Elements, Mechanical Property, Metallographic Test, HIC /SSC, Heat Treatment, Ultrasonic Test, Penetration Test, Magnetic Powder Test, X-Ray Test, Hydraulic Pressure Test, Blasting Experiment, we can make them according to your request. |

| Application | Water Disposal, Electric Power, Chemical Engineering, Ship Building, Nuclear Energy, Garbage Disposal, Natural Gas, Petroleum Oil. |

Advantages of Buttweld Fittings

- Welding butt-weldable fitting to a piping system, ensures a 100% leak proof connection.

- The piping system which uses a buttweld fittings requires less space.

- The continuous metal structure formed due to welding of a buttweld fitting to pipes gives enough strength to the system.

- Smooth inner surface and gradual direction results in lower pressure loss, and lower corrosion or abrasion resistance.

- Various turning options and easy to weld.

- Buttweld saves more cost than socket weld or threaded.

- Allow thin thickness as SCH 10 or SCH 10S.

- Compatible with different sizes from 1/4 inch to 24 inch and up to 72 inch.

What are Advantages of Buttwelding over Flanges?

- Flanges connect pipes by bolting them together, whereas buttwweld fittings connect pipes by welding them together.

- Depending on size, buttweld fittings require 10% to 75% less material than a flanged connection, which means lower material cost and lower weight.

- Welded construction permits greater freedom in designing a layout; this system uses less space, is more compact, and has greater strength.

- Buttweld fittings provide optimum flow characteristics, without pockets or sharp corners, creating less frictional resistance, no pressure loss, less turbulence.

- The welded connection would help to get more robust connection.

- Continuous structure of metal would add to the strength of the piping system.

- When buttweld fittings would be matched with the appropriate pipe schedules, they would help to offer a seamless flow inside the pipe.

- It provides the option of various turn radius by using Long Radius, Short Radius, or 3R elbows.

- Found to be cost effective compared to the socket weld or threaded counterparts.

- These fittings would be available in Schedule 10, thus allowing for a thinner wall option.

- These fittings have been found to be more common in the configuration of Schedule 10 and Schedule 40.

Fittings are divided into three groups:

- Buttweld (BW) fittings whose dimensions, dimensional tolerances et cetera are defined in the ASME B16.9 standards. Light-weight corrosion resistant fittings are made to MSS SP43.

- Socket Weld (SW) fittings Class 3000, 6000, 9000 are defined in the ASME B16.11 standards.

- Threaded (THD), screwed fittings Class 2000, 3000, 6000 are defined in the ASME B16.11 standards.

Standard Types of Buttweld Fittings

- Pipe Elbows – Steel elbow is used to be installed between two lengths of pipe or tube allowing a change of direction, usually these carbon steel elbows distinguished by connection ends.

- Pipe Bend – Pipe bend can be made of variety materials, like carbon steel, alloy steel, stainless steel, low temperature steel or high-performance steel, etc.

- Pipe Tees – We can provide seamless tube tees and welding tube tees, which can also be divided into straight tees and reducing tees. Usually, the pipe tees have the same inlet and outlet sizes.

- Pipe Cross – A pipe fitting, having four openings in the same place, at right angles to each other. A pipe cross is a kind of pipe fitting. It is used in the place where four pipes meet together. The pipe cross may have one inlet and three outlets, or three inlets and one outlet.

- End Caps – End Cap, Carbon Steel cap, Stainless Steel Caps, ANSI, ISO, JIS and DIN Standards, Measures 1/2 to 56 Inches. Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

- Pipe Reducer – Pipe reducer are tube fittings that are widely used in a number of industries in order to providing greatest connection flexibility in connecting fractional tubes in various installations.

- Stub End – Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End.

- Coupling Fittings – Coupling fittings are used for fluid conduits in which each end portion of two tubes to be connected is provided with a swaged-on adapter carrying the necessary means to connect or disconnect the tubes without disturbing the swaged-on adapter.

Standards and Specifications for Buttweld Pipe Fittings

| Standard | Grade and Specification |

| ASME | ANSI B16.9, ANSI B16.28, MSS-SP-43 |

| DIN | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN | EN10253-1, EN10253-2 |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.28 | Wrought Steel Short Radius Elbows and Buttwelding Returns |

| MSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

Materials and Grades for Buttweld Pipe Fittings

| Material | Grade |

| Carbon Steel | WPB, WPC, WPL6 |

| Chrome Moly | WP5, WP9, WP11, WP12, WP22 |

| Stainless Steel | 304/304L, 316/316L, 304H, 316H, 309, 310S, 317L, 321/321H, 347/347H, 904L, DUPLEX 2205 / SUPER DUPLEX 2507 |

| High Yield Carbon Steel | WPHY42, WPHY52, WPHY65 |

| Nickel Alloys | Alloy 20, 200, 201, 400, 600, 625, 800H/HT, 825, 254SMO, AL6XN, C276, C22, B3, HAST-X |

| Standard Materials | Carbon, Stainless, Chrome Moly, High Yield, Low Temperature, Aluminum |

| Types | Elbows, Tees, Reducers, Caps, Stub Ends, Crosses, Laterals, Olets, Return Bends |

| Sizes | Standard 1/2″ to 48″ (special order larger O.D. fittings) |

| Wall Sizes | Schedule 20 thru XXH, and Special Wall Sizes |

| Specialty Items | 3D & 5D Bends, Galvanizing, 100% X-ray Testing |

Chemical Composition and Mechanical Properties of Buttweld Pipe Fittings

1. Carbon Steel Buttweld Pipe Fittings

ASTM A234 WPB is the Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service.

| ASTM | A234 WPB |

| ASME | B16.9, B.11 |

| NACE | MRO175 |

| MSS | SP-83, SP-95 |

Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | Others |

| – | – | – | max | max | – | – | – | – | – | – |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1 | 0.4 | 0.15 | 0.4 | 0.4 | V 0.08 |

| (1,2,3,4,5) | max | – | – | – | min | max | max | max | max | max |

2. Stainless Steel Buttweld Pipe Fittings

Stainless buttweld fittings are available in 316 and 304 grades.

| Types | Caps – Crosses – Elbows – Reducers – Stub Ends – Tees |

| Sizes | 1/2″ – 36″ + |

| Schedules | S/5s – XXH |

| Alloys | Aluminium – Carbon – Nickel Alloys – Stainless |

Chemical Composition

| C | Cr | Mn | Ni | P | S | Si | Mo | |

| MAX | – | MAX | – | MAX | MAX | MAX | ||

| 304/304L | 0.035 | 18.0- 20.0 | 2 | 8.0-13.0 | 0.045 | 0.03 | 1 | – |

| 316/316L | 0.035 | 16.0- 18.0 | 2 | 10.0-14.0 | 0.045 | 0.03 | 1 | 2.0-3.0 |

Mechanical Properties

| 304/304L | 316/316L | |

| Tensile Strength (KSI) | 60 | 70 |

| Yield Strength (KSI) | 35 | 25 |

| (KSI converts to MPA {Megapascals} by multiplying by 6.895) | ||

3. Carbon and Alloy Steel Buttweld Pipe Fittings

The ASTM A420 WPL6 steel pipe fittings means the buttwelding pipe fittings whose material is ASTM A420 grade WPL6.ASTM A420 is standard specification for piping fittings of wrought carbon steel and alloy steel for low-temperature service. So A420 WPL6 fittings are specially used in low temperature conditions.

Chemical Composition

| Grade | C | Mn | P | S | Si |

| WPL6(1)(2) | 0.3 | 0.60-1.35 | 0.035 | 0.04 | 0.15-0.30 |

Mechanical Properties

| Tensile Strength min, ksi [MPa] | 60-85[415-585] |

| Yield Strength min, ksi [MPa] | 35[240] |

Buttweld Dimensions

- Buttwelded Pipe Fittings Dimensions refer to pipe size standards ANSI B36.10 and B36.19.

- Diameter range: 1″, 2″, 3″, 4″, 6″, 8″ and maximum 72″.

- Thickness range: Schedule 10, Schedule 40, Schedule 80, XS, XXS and SCH 160

- In the case of involving mounting dimensions of buttwelded fittings, this will include the diameter in the NPS and the thickness in the schedule.

What is a Seamless Buttweld Fittings?

- A seamless buttweld pipe fitting is made directly from a section of seamless pipe material, by applying heat and pressure to transform pipe directly into an elbow or other shape.

- A seamless fitting has no welded parts by itself, a characteristic demanded in some critical applications.

- By comparison, a regular buttweld fitting has one, two or more welds, depending on dimension, shape and manufacturing method.

- No weld means less risk of weld yield and porosities.

Applications of Buttweld Pipe Fittings

Fittings are used wherever liquids, gases, chemicals and other fluids are created, processed, transported, or used. Range of industries is very wide, as shown below:

- Energy related – Oil and gas industries, including upstream (exploration and production), midstream (transportation by ships, pipeline, rail, trucks; storage and wholesale) and downstream (refining into fuels or chemicals; marketing and distribution). Power plants using fossil or nuclear fuels. Geothermal energy for harnessing heat from the earth.

- Food and beverage production – From basic ingredients to elaborate desserts. From milk, to juices and other beverages. Cold chain to keep produce fresh, drinks and frozen foods at a set temperature. Desalination plants to transform seawater into drinking water for arid areas and various tropical islands.

- Pharmaceuticals and biotech production – Medicines and vaccines that treat illnesses and help restore bodies and minds to their top conditions.

- Semiconductor manufacturing – Microchips that go into all electronics, including smartphones, tablets, computers, television sets, telecom networks.

- Pulp and paper production – Newsprint, glossy paper, cardboard boxes, books, writing paper.

- Production of construction materials and plastics – From roofing materials, to glassmaking for windows, to copper wiring for transporting electricity, and various plastics throughout houses and office buildings.

Testing & Inspection of Buttweld Pipe Fittings

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Buttweld Pipe Fittings

Prices for buttweld pipe fittings are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy plates is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of buttweld pipe fittings, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our price list for various steel products on our blog.

Documents Provided at the time of Domestic Sales or Export of Buttweld Pipe Fittings

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Basis for Buttweld Pipe Fittings

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Buttweld Pipe Fittings

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Suppliers of Buttweld Pipe Fittings in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Export Sales of Buttweld Pipe Fittings

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu