Pipe End Caps Manufacturers, ASME B16.9 End Caps Manufacturers, Suppliers, Stockist – Buttweld End Caps

- Metallica is a prominent manufacturer of pipe end cap fittings in India, with butt-welding ends. It is a type of buttweld fitting. Our products are quality certified, and are supplied with relevant test certificates. We specialise in producing custom size stainless steel end caps, carbon steel end caps and alloy steel end caps.

- A pipe end cap, as its name suggests, is a cap that goes over the end of a pipe, creating a dead end. There are a good number of ways a cap can be applied to the pipe like soldering, glue, or threading depending on the material of the pipe.

- In addition to buttweld pipe end caps, we also manufacture elbows, tees, bends, reducers, flanges and sockets. Our production range for buttweld end caps is 1/2″-48″. We have been in this line for about 40 years. Our products are exported to many countries and regions in Southeast Asia, the Middle East, Europe and America.

Materials for Manufacturing Pipe End Caps

| Stainless Steel | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Steel | ASTM A 182 – F 51, F53, F55, UNS S31803, UNS S32205, UNS S32750, UNS S32760 |

| Carbon Steel | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C |

| Alloy Steel | ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Copper Alloy Steel | ASTM/ASME SB 111 UNS NO. C10100, C10200, C10300, C10800, C12000, C12200, C70600, C71500, ASTM / ASME SB 466 UNS NO. C70600 ( CU -NI- 90/10), C71500 ( CU-NI- 70/30) |

| Nickel Alloy Steel | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

Stock and Production Range of Pipe End Caps

| Product | Pipe End Caps |

| Connection | Buttweld |

| Type | Seamless |

| Standard | ASME B16.9 |

| Size | 1/2″ to 48″ NPS |

| Thickness | SCH 5 to SCH XXS, Upto 40mm |

| Certification | EN 10204 3.1 |

Materials-Standards for ASME B16.9 Fittings

| ASTM Standards | Material Specification |

| A234 | Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

| A403 | Wrought Austenitic Stainless Steel Piping Fittings |

| A420 | Wrought Carbon Steel and Alloy Steel for Low Temperature Service |

| A815 | Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Piping Fittings |

| A361 | Wrought Aluminum and Aluminum Alloy Welding Fittings |

| A363 | Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding Fittings |

| A366 | Wrought Nickel and Nickel Alloy Fittings |

Dimensions Butt Weld Caps NPS 1/2 – 48 ASME B16. 9

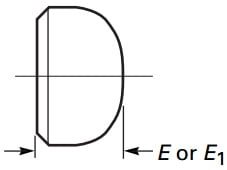

- Technical Drawing & Dimensions for ASME B16.9 Pipe End Caps

| Nominal Size | Outside | Length, E | Limiting Wall | Length, E1 |

| Diameter | Thickness | |||

| at Bevel | for Length, E | |||

| NPS | mm. | mm. | mm. | mm. |

| in. | in. | in. | in. | |

| 1/2 | 21.3 | 25 | 4.57 | 25 |

| 0.84 | 1 | 0.18 | 1 | |

| 3/4 | 26.7 | 25 | 3.81 | 25 |

| 1.05 | 1 | 0.15 | 1 | |

| 1 | 33.4 | 38 | 4.57 | 38 |

| 1.32 | 1.5 | 0.18 | 1.5 | |

| 1 1/4 | 42.2 | 38 | 4.83 | 38 |

| 1.66 | 1.5 | 0.19 | 1.5 | |

| 1 1/2 | 48.3 | 38 | 5.08 | 38 |

| 1.9 | 1.5 | 0.2 | 1.5 | |

| 2 | 60.3 | 38 | 5.59 | 44 |

| 2.38 | 1.5 | 0.22 | 1.75 | |

| 2 1/2 | 73 | 38 | 7.11 | 51 |

| 2.88 | 1.5 | 0.28 | 2 | |

| 3 | 88.9 | 51 | 7.62 | 64 |

| 3.5 | 2 | 0.3 | 2.5 | |

| 3 1/2 | 101.6 | 64 | 8.13 | 76 |

| 4 | 2.5 | 0.32 | 3 | |

| 4 | 114.3 | 64 | 8.64 | 76 |

| 4.5 | 2.5 | 0.34 | 3 | |

| 5 | 141.3 | 76 | 9.65 | 89 |

| 5.56 | 3 | 0.38 | 3.5 | |

| 6 | 168.3 | 89 | 10.92 | 102 |

| 6.62 | 3.5 | 0.43 | 4 | |

| 8 | 219.1 | 102 | 12.7 | 127 |

| 8.62 | 4 | 0.5 | 5 | |

| 10 | 273 | 127 | 12.7 | 152 |

| 10.75 | 5 | 0.5 | 6 | |

| 12 | 323.8 | 152 | 12.7 | 178 |

| 12.75 | 6 | 0.5 | 7 | |

| 14 | 355.6 | 165 | 12.7 | 191 |

| 14 | 6.5 | 0.5 | 7.5 | |

| 16 | 406.4 | 178 | 12.7 | 203 |

| 16 | 7 | 0.5 | 8 | |

| 18 | 457 | 203 | 12.7 | 229 |

| 18 | 8 | 0.5 | 9 | |

| 20 | 508 | 229 | 12.7 | 254 |

| 20 | 9 | 0.5 | 10 | |

| 22 | 559 | 254 | 12.7 | 254 |

| 22 | 10 | 0.5 | 10 | |

| 24 | 610 | 267 | 12.7 | 305 |

| 24 | 10.5 | 0.5 | 12 | |

| 26 | 660 | 267 | – | – |

| 26 | 10.5 | |||

| 28 | 711 | 267 | – | – |

| 28 | 10.5 | |||

| 30 | 762 | 267 | – | – |

| 30 | 10.5 | |||

| 32 | 813 | 267 | – | – |

| 32 | 10.5 | |||

| 34 | 864 | 267 | – | – |

| 34 | 10.5 | |||

| 36 | 914 | 267 | – | – |

| 36 | 10.5 | |||

| 38 | 965 | 305 | – | – |

| 38 | 12 | |||

| 40 | 1016 | 305 | – | – |

| 40 | 12 | |||

| 42 | 1067 | 305 | – | – |

| 42 | 12 | |||

| 44 | 1118 | 343 | – | – |

| 44 | 13.5 | |||

| 46 | 1168 | 343 | – | – |

| 46 | 13.5 | |||

| 48 | 1219 | 343 | – | – |

| 48 | 13.5 |