SS 316 Seamless & Welded Pipe Suppliers in Rajkot

Warmly welcome customers home and abroad to visit our company and give us valuable suggestions. We would like to have long term cooperation with customers from all over the world on the basis of mutual prosperity and development.

Stainless steels are defined as ferrous alloys with the addition of at least 10.5% chromium by weight and are essentially low carbon steels containing significant amounts of chromium. It is the addition of chromium that gives this type of steel its corrosion resisting properties.

The chromium content of the steel allows the formation of an invisible corrosion resistant chromium oxide film on the steel surface. If damaged mechanically or chemically this film is self-healing providing that oxygen, even in very small amounts, is present. The corrosion resistance of stainless steel can be enhanced along with providing other useful properties by increasing the chromium content and by adding other elements such as molybdenum, nickel, and nitrogen.

The city contributes to the economy of the state with heavy and small scale industries under the patronage of Gujarat Industrial Development Corporation (GIDC) and Gujarat State Financial Corporation (GSFC). Rajkot was formerly the leading centre in India in the field of diesel engine and submersible pumps. Submersible pumps are still manufactured in the city and marketed throughout India, with some of the larger manufacturers also exporting them. Industrial products include bearings, diesel engines, kitchen knives and other cutting appliances, watch parts (cases and bracelets), automotive parts, forging industry, casting industry, machine tools, share market and software development.The city is also home to several CNC machine and auto parts manufacturers.

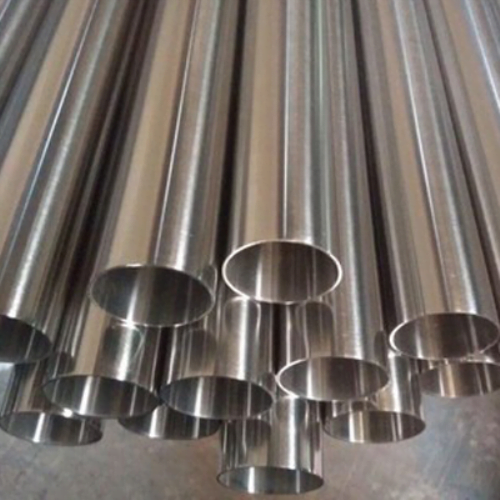

Manufacturing Range for 316 Stainless Steel Seamless & Welded Pipes

| Product | TP316, 1.4401, UNS S31600 Stainless Steel Pipes |

| Specification | ASTM A213, ASTM A249, ASTM A269, ASTM A270, ASTM A312, ASTM A358 CL. I to V, ASTM A403, ASTM A554, ASTM A632, ASTM A789, ASTM A790 TP316 |

| Type and Form | Seamless & ERW/EFW/LSAW Welded,Fabricated, Round, Square, Rectangular, Hydraulic, Large Diameter 100% X-Ray Welded |

| Size Range | Size: 6″NB to 100″NB – EFW |

| Size:1/2”NB to 24” NB – ERW |

| 1/8” NB to 30” NB – Tubing Size |

| 1/2” NB to 24” NB – Pipes and Tubes Size |

| Thickness | SCH20, SCH30, SCH40, STD, SCH60, SCH80, XS, SCH120, SCH140, SCH160 |

| Wall Thickness: 5S – XXS (Heavier On Request) |

| End | Plain End, Beveled End, Threaded |

| Length | 6 Meter, Custom Lengths, Single Random, Double Random |

| Other Grades | TP304, TP304L, TP304LN, TP316, TP316Ti, TP316H, TP316L, TP316LN, TP317, TP317/317L, TP321, TP347, TP310S |

| Test Certificates | Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 |

| ASTM Reference Standards | - A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels.

- A370 Test Methods and Definitions for Mechanical Testing of Steel Products.

- A480 A480M Specification for general requirements for Flat-rolled stainless and Heat-Resisting steel plate, sheet, and strip.

- A632 Specification for Seamless and welded austenitic stainless-steel tubing (small-diameter) for general service.

- A1016 A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless-Steel Tubes.

- E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

|

| Testing | Mechanical Testing Such as Tensile of Area, Hardness Test, Chemical Analysis – Spectro Analysis, Positive Material Identification – PMI Testing, Flattening Test, Micro and MacroTest, Pitting Resistance Test, Flaring Test, Intergranular Corrosion (IGC) Test |

| Documents | Commercial Invoice, Packing List, Certificate of Origin, Fumigation Certificates, Raw Material Test Reports, Material Traceability Records, Quality Assurance Plan (QAP), Heat Treatment Charts, Test Certificates certifying NACE MR0103, NACE MR0175, Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Guarantee Letter, NABL approved Laboratory Test Reports |

Chemical Composition of AISI 316 Seamless or Welded Stainless Steel Pipes

| ELEMENT | 316 | 316L | 316TI |

| NI | 11.0 – 14.0 | 10.0 – 14.0 | 10.0 – 14.0 |

| C | 0.08 max | 0.035 max | 0.08 max |

| MN | 2.0 max | 2.0 max | 2.0 max |

| P | 0.045 max | 0.045 max | 0.045 max |

| S | 0.30 max | 0.30 max | 0.30 max |

| SI | 1.0 max | 1.0 max | 0.75 max |

| CR | 16.0 – 18.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| MO | 2.0 – 3.0 | 2.0 – 3.0 | 2.0 – 3.0 |

| TI | | | 5x(C+N) – 0.70 |

| N | | | 0.10 max |

Comparison of Chemical Composition of Various Stainless Steel Grades

| Grade | UNS | Composition, % in Max. |

| Designation | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | . . . |

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–13 | . . . | . . . |

| TP304LN | S30453 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | 0.10-0.16 |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | . . . |

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–15 | 2.00–3 | . . . |

| TP316LN | S31653 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–13 | . . . | 0.10-0.16 |

| TP317L | S31700 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 11.0–15 | 3.0–4 | . . . |

| TP321 | S32100 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–12 | . . . | . . . |

| TP347 | S34700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . |

Properties of SS 316, SS 316L and 316Ti Seamless or Welded Stainless Steel Pipes

| DENSITY | 7.99 g/cm 3 / 0.29 lb/in 3 |

| MELTING POINT | 1371 – 1399 (°C) / 2500 – 2550 (°F) |

| ANNEALED | 1040 (°C) / 1900 (°F) |

| QUENCH | Rapid Air/Water |

Mechanical Properties Comparision of 316 Stainless Steel Pipes

| Grade | UNS Designation | Tensile Strength, Min. Ksi [MPa] | Yield Strength, Min. Ksi [MPa] |

| TP304 | S30400 | 75 [515] | 30 [205] |

| TP304L | S30403 | 70 [485] | 25 [170] |

| TP316 | S31600 | 75 [515] | 30 [205] |

| TP316L | S31603 | 70 [485] | 25 [170] |

| TP317L | S31703 | 70 [485] | 25 [170] |

| TP321 | S32100 | 75 [515] | 30 [205] |

| TP347 | S34700 | 75 [515] | 30 [205] |

| TP347H | S34709 | 75 [515] | 30 [205] |

Grade Specification & Equivalents Comparison

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS |

| | BS | En | No | Name | | |

| 316L | S31603 | 316S11 | – | 1.4404 | X2CrNiMo17-12-2 | 2348 | SUS 316L |