Description

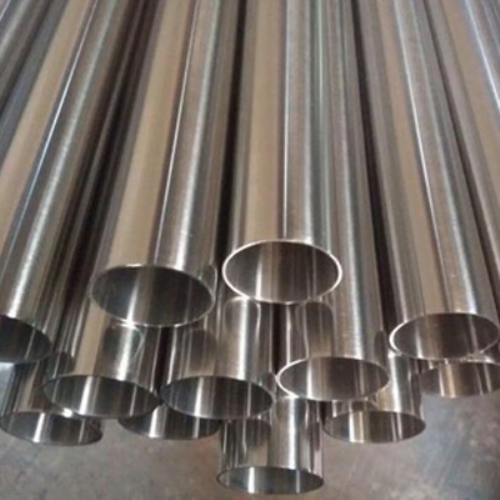

A249 TP316 Stainless Steel Pipes/Tubes Manufacturers & Suppliers in India

Largest Manufacturer and Suppliers of Welded Austenitic Steel Boiler, Superheater, Heat Exchanger, and Condenser Tubes of ASTM A249 TP316 specification. Metallica manufactures stainless steel tubing from the finest quality raw materials. Stainless steel tubes in grade TP304, TP304L, TP316, TP316L and TP201 are generally available in stock in size range of 1/8” NB to 5” NB, 1/4” OD to 5” OD sizes.

Stainless Steel 316 is the standard molybdenum-bearing grade, second in importance to SS 304 amongst the austenitic stainless steels. The molybdenum gives SS 316 better overall corrosion resistant properties than Stainless Steel 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. Stainless Steel 316 has excellent forming and welding characteristics. It is readily brake or roll formed into a variety of parts for applications in the industrial, architectural, and transportation fields. SS 316 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

Stainless Steel A249 TP316 Pipes & Tube Supply Range

| Size | 1/8” NB to 5” NB, 1/4” OD to 5” OD sizes |

| W.T | 1.20-2.11 mm |

| Standard | ASTM A249 |

| Grades | 201 / 304 / 304L / 308 / 309S / 316 / 316L / 321 / 409L |

| Length | Upto 6m, Custom Cut Lengths |

| Surface treatment | No.1 Pickled Finish, No.4 finish, BA Finish, Electropolished Pipe |

Chemical Composition for Stainless Steel Pipes & Tubes, A249 TP316

| Grade | UNS | Composition, % |

| Design | C | Mn | P | S | Si | Cr | Ni | Mo |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14.0 | 2.00–3 |

Mechanical Properties for Stainless Steel Pipes & Tubes, A249 TP316

| Material | Heat | Temperature | Tensile Strength | Yield Strength | Elongation %, |

| Treatment | Min. º F(º C) | Ksi (MPa), Min. | Ksi (MPa), Min. | Min |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

Quality and Mechanical Tests for Stainless Steel Pipes & Tubes as per ASTM A249 TP316

To assure the highest quality standards, the tubing is subjected to extensive testing and inspection programs that meet or exceed ASTM A249 test requirements. The steel shall undergo mechanical tests such as tension test, flattening test, flange test, reverse-bend test, hardness test, and hydrostatic/eddy current testing/nondestructive electric test. The grain size of different grades of steel shall be determined in accordance with the test methods.

Heat Treatment (Annealing) for Stainless Steel Pipes & Tubes as per ASTM A249 TP316

A249, A269 and A270 follows that “all material shall be furnished in the heat treated condition”. Heat treatment is annealing (also referred to as solution treatment or solution annealing). In practice this is not a common requirement for food industry tube unless it requires significant bending or flaring. All materials shall be furnished in the heat-treated condition in accordance with the required solution temperature i.e. minimum of 1900 degrees F and quenching method. A249 TP316 requires that at least the weld be cold worked after welding and before final heat treatment. When the final heat treatment is in a continuous furnace, the number of tubes of the same size and from the same heat in a lot shall be determined from the prescribed size of the tubes.

Surface Finishes for Stainless Steel Pipes & Tubes as per ASTM A249 TP316

The tubes, after heat treatment, shall be chemically descaled or pickled free of scale. Pickling or chemical descaling is not needed if bright annealing is used.

Flattening Test for Stainless Steel Pipes & Tubes as per ASTM A249 TP316

For material heat treated in a continuous furnace flattening tests shall be made on a sufficient number of pipes to constitute 5 % of the lot, but in no case less than 2 lengths of pipe.

Markings for Stainless Steel Pipes & Tubes as per ASTM A249 TP316

Manufacturer Name or brand, specification number and grade on tube. For tubes less than 1 1/4″ in diameter or under 3″ in length, a tag may be secured to the box or bundle.

Note:

- Mill test certificates will be issued according to EN10204.3

- All tubes shall be supplied as per applicable ASTM A249 /A249M Specification.

Related Keywords:

austenitic stainless steel; boiler tubes; condenser tube; heat exchanger tube; high temperature applications; steel tube; superheater tubes; temperature service applications, high; welded steel tube and heavily cold worked (HCW) tubes; Austenitic stainless steel tube–specifications; Boiler/superheater tubes–specifications; Condenser and heat exchanger systems–steel; High-temperature service applications–steel tube; Superheater tubes–specifications; Welded steel tube–specifications;