Stainless Steel Forged Pipe Fittings Manufacturers, Suppliers, Stockist – Socket Weld Pipe Fittings, Stainless Steel Threaded Pipe Fittings Factory – ANSI B16.11

| 304/1.4301 Stainless Steel Forged Pipe Fitting | 321/1.4541 Stainless Steel Forged Pipe Fitting |

| 304L/1.4307 Stainless Steel Forged Pipe Fitting | 317L/1.4449 Stainless Steel Forged Pipe Fitting |

| 304H/1.4948 Stainless Steel Forged Pipe Fitting | 347H/1.4912 Stainless Steel Forged Pipe Fitting |

| 316/1.4401 Stainless Steel Forged Pipe Fitting | 309S/1.4833 Stainless Steel Forged Pipe Fitting |

| 316L/1.4404 Stainless Steel Forged Pipe Fitting | 310S/1.4845 Stainless Steel Forged Pipe Fitting |

| 316Ti/1.4571 Stainless Steel Forged Pipe Fitting | 904L Stainless Steel Forged Pipe Fitting |

- Size: from 1/4″ to 4″ (6mm-100mm), Pressure: 2000LBS, 3000LBS, 6000LBS, 9000LBS

- Stainless Steel Threaded Pipe Fittings – 90° Elbow, 45° Elbow, Tee, Cross, Full Coupling, Half Coupling, Reducing Coupling, Pipe Cap, Hex Head, Bushing, Hex Head Plug, Square Head Plug, Round Head Plug, Union, Hex Nipple, Street Elbow, Bull Plug, Boss, Swage Nipple, Pipe Nipple, Adapter, Union (Male x Female), Branch Outlet, 90° Elbow Outlet, 45° Lateral Tee, Lateral Outlet, Nipple Branch Outlet

- Stainless Steel Socket Weld Pipe Fittings – 90° Elbow, 45° Elbow, Tee, Cross, Full Coupling, Half Coupling, Pipe Cap, Union, Reducer Insert, Boss, Branch Outlet, 90° Elbow Outlet, 45° Lateral Tee, Lateral Outlet, Branch Outlet Butt Weld, 90° Elbow, Outlet Butt Weld, Lateral Outlet Butt Weld, Nipple Branch Outlet Butt Weld

Metallica is a well known manufacturer and supplier of stainless steel forged pipe fitting for the clients from oil and gas, petrochemicals, railway, construction and other industries. We manufacture different size and shapes of stainless steel forged pipe fittings by open die forging, closed die forging and drop forging. Our main products include stainless steel socket weld and stainless steel threaded pipe fittings in size range of 1/4″ to 4″ (6mm-100mm), with pressure rating of 2000LBS, 3000LBS, 6000LBS, and 9000LBS.

Stainless Steel Forged Pipe Fittings Manufacturers

Forged Pipe Fittings Manufacturing Standards

- ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

- ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

- ASME B16.11 – Socket Welding and Threaded Forged Fittings

- MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

- MSS SP-95 – Swage(d) Nipples and Bull Plugs

- BS3799 – Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry

Stainless steel forged socket weld and stainless steel threaded pipe fittings are generally used for small size pipes and piping systems (generally below 4 inches in diameter for Class 3000, and below 2 inches for fittings in class 6000 and 9000). Stainless steel forged pipe fittings are manufactured by forging, followed by heat treatment and machining solid steel as per ASME B16.11 and other dimensional standards. For bigger size piping systems buttweld pipe fittings produced as per ASME B16.9 are used.

Product Specification for Stainless Steel Forged Pipe Fittings

| Product | Stainless Steel Forged Fittings |

| Type | Pipe Union, Cross, Elbow, Tee, Half Coupling, Full Coupling, Branch Outlets, Forged Plug, Hexagon Bushing |

| Connection | Thread/NPT (M/F), Socket Weld, Screwed |

| Applications | Oil and Gas Industry, Chemical Industry, Electric Power, Shipping |

| Pressure Rating | 2000#, 3000#, 6000#, 9000# or 2000LB, 3000LB, 6000LB, 9000LB |

| Type | Pipe Union, Cross, Elbow, Street Elbow, Tee, Half Coupling, Full Coupling, Branch Outlets, Forged Plug, Hexagon Bushing, Plugs, Inserts, Caps |

| Process method | Forged, CNC Machined |

| Materials Grades | ASTM/ASME SA/A182 F304, F304L, F316, F316L, F321, F321H, F347, F347H |

| Standards: | ASME/ANSI B16.11, MSS SP 83, MSS SP 97, MSS SP 95 |

| Forged Size |

|

| Condition | Anneal, Normalize, Normalize + Temper, Quench + Temper, as requirements |

| Inspection Testing | Mechanical Test, Hardness Test, Inter-granular corrosion Test, Ultrasonic Test, PT, MT, Hydraulic Test, or as required |

| Certificate | EN 1024 3.1/ 3.1B/ 3.2, PED, DNV, TUV. |

| Packing | Wooden case/ Steel framed plywood case/ simple packing. |

| Delivery Time | By mutual agreement. |

| We also can provide High quality Special Alloys forgings as well as non-standards forgings. Forged Fittings are available in both socket weld and threaded ends. | |

Forged Fittings Materials & Grades

| Carbon Steel | ASTM A105/N, ASTM A350LF2, LF3, LF6 |

| Duplex | 2205(F51/60), 2507(F53) |

| Chrome Moly | SA182, F1, F5, F5a, F9, F9l, F11, F12, F22 |

| Stainless Steel | 304/L/H, 316/L/H, 310, 317L, 321/H, 347/H, 410, 416, 420, 17-4, 440, Alloy 20 |

| Nickel Alloys | 200, 201, 400, K500, 600, 625, 800H/HT, 825, X-750, C276, Hastelloy B & C22 |

Manufacturing Process for Stainless Steel Forged Pipe Fittings

- Forged fittings are the fittings made by forged steel. The process of manufacturing forged steel fittings include: cutting and heating billets, put pressure on heated billets under dies into desired shape, trimming and shot blasting. Then machine forged blank fittings for net shape and dimensions. According to the applications of forged steel fittings, they are available in threaded and socket weld end connections.

- The main raw material for producing forged pipe fittings is round bar stock or billets.

- Most of the forged steel fittings are not large, so closed die forging is normally adapted to produce forged steel fittings. Compared to the open die forging, the close die forging can achieve more complex geometries, very much close to the dimensions of the finished component.

- Close die forging can produce forged fittings in all materials such as carbon steel, duplex, stainless steel or nickel alloys.

- Forged Fittings are manufactured from seamless pipe and from welded pipe with filler material (ERW & EFW pipes cannot be used to manufactured fittings). Large diameter fittings are manufactured from Plate. There are various forged pipe fittings manufacturing process that used to manufactured Elbow, Tee, Reducers and other pipe fittings.

- Mandrel Method – Hot forming or Extrusion Method

- Hydraulic Bulge method – Cold forming

- UO or Single weld seam Method

- Monaka or Double weld seam Method

- Deep Drawing Method for caps

- Flare Method for Stub ends

- The equipment used to produce forged fittings varies with respect to the forging processes which can be carried out:

• The method of applying the force.

• The size.

The different types of forging equipment include:

• Hammers

• Presses

• Upsetters

• Forging Rolls

• Ring Rollers

• Swaging Machines

Types of Stainless Steel Socket Weld & Threaded Forged Steel Pipe Fittings

- Elbows (90 Degree Elbows and 45 Degree Elbows) – A pipe elbow is a forged steel fitting installed between two lengths of pipe or tube allowing a change of direction, usually in the 90° or 45° direction. Similar to a reducing tee, reducing elbows also exist to simultaneously change flow direction and reduce flow diameter. Street Elbows have one female end to accept pipe and another male end thread that is the same size as the pipe and can avoid the use of a pipe nipple during installation.

- Tees (Equal Tee and Reducing Tees)- Tees are a type of forged steel fitting used to combine or divide process flow, and Reducing Tees additionally allow for pipe size change. The run outlets of the tee are the two in-line outlets, and the branch is the third outlet. The branch outlet is the reducing outlet in a reducing tee.

- Couplings (Straight and Reducing Couplings, Full and Half Couplings) – Couplings are a forged steel fitting used to connect two lengths of pipe, and Half-coupling is screwed onto the pipe, while the other end is made to be tightly inserted, or welded, onto the other end to pipe or vessel. Standard Couplings have female threads or open sockets at both ends, whereas reducing couplings connect smaller pipes to larger ones.

- Unions (Socket Weld Unions and Threaded Unions) – Unions are a forged steel fitting similar to a coupling but allow a convenient disconnection and connection; it has 3 parts: a nut, a female end, and a male end. They allow two lengths of pipe to be assembled and detached without causing any deformation to the pipes.

- Bushings (Hex Head Bushings and Flush Bushings) – Reducing inserts and Bushings are forged steel fittings that allow for a change in pipe size. Pictured here is the hex head bushing, which is most commonly used.

- Caps (Pipe Caps and End Caps) – Caps are forged steel fittings used to terminate the flow, inserting over the end of the pipe.

- Plug (Square Head Plugs, Hex Head Plugs and Round Head Plugs) – Similar to a cap, plugs are forged steel fittings that are inserted into the end of the pipe, and they come with different head types, including: hex, square, and round.

- Cross – Crosses are a 4-way forged steel fitting, with 1 inlet and 3 outlets or vice versa. These are sometimes referred to as 4-way tees.

- Outlets (Weldolets, Sockolets, Threadolets, Elbolets, Latrolets and Nipolets)

- Nipples (Hexagonal Nipples and Swaged Nipples)

Chemical Composition of Stainless Steel Forged Pipe Fittings

| Chemical Composition % | |||||||||

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | N |

| 201 (1Cr17Mn6Ni5N) | ≤0.15 | ≤1.0 | ≤5.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | — | ≤0.25 |

| 202 (1Cr18Mn8Ni5N) | ≤0.15 | ≤0.07 | ≤7.5 | ≤0.06 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | — | ≤0.25 |

| 304 0Cr18Ni9) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 304L (00Cr18Ni10) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 316 (0Cr17Ni12Mo2) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 316L (0Cr17Ni14Mo2) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.04 | ≤0.03 | 9.0-12.0 | 17.0-19.0 | Ti≥5xC | |

| 409 | ≤0.08 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ≤0.5 | 10.5-11.7 | Ti6xC%≤0.70 | |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 0.5 | 10.5-11.7 | Ti8xC%≤0.70 | |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 16.0-18.0 | |||

How to Determine Whether Forging or Casting to be done?

- Steel products may be manufactured either by casting or forging steel. Steel casting is the process by which a metal is heated until it reaches a liquid state and then poured into a mold that shapes the desired product. In Steel forging method, steel is physically forced into shape while remaining in a solid state – although it is frequently heated.

- Forged parts had a 26% higher tensile strength than the cast parts. This means you can have stronger shackles at a lower part weight. The reason behind is when you melt metal to cast it, the grain size is free to expand. When it cools back to a solid, the grain structure is courser and more random, decreasing its strength.

- Forged parts have a 37% higher fatigue strength resulting in a factor of six longer fatigue lives. This means that a forged shackle is going to last longer.

- Cast steel only has 66% of the yield strength of forged steel. Yield strength is an indicator of what load a shackle will hold before starting to deform.

- The forged parts had a 58% reduction in area when pulled to failure. The cast parts only had a 6% reduction in area. That means there would be much greater deformation before failure in a forged part.

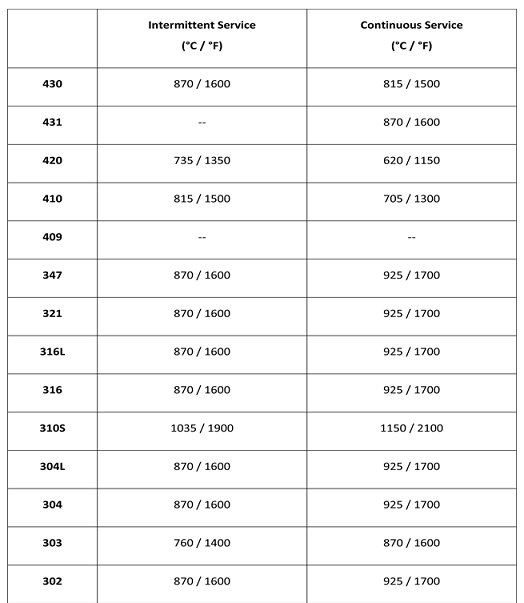

What are the Maximum Operating Temperatures of Stainless Steel Grades?

Stainless steels have good strength and good resistance to corrosion and oxidation at elevated temperatures. Stainless steels are used at temperatures up to 1700° F for 304 and 316 and up to 2000 F for the high temperature stainless grade 309(S) and up to 2100° F for 310(S).

[Image Source: From Web]

Testing & Inspection of Stainless Steel Forged Pipe Fittings

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Stainless Steel Forged Pipe Fittings

Prices for stainless steel forged pipe fittings are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy plates is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of stainless steel forged pipe fittings, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our price list for various steel products on our blog.

Documents Provided at the time of Domestic Sales or Export of Stainless Steel Forged Pipe Fittings

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Basis for Stainless Steel Forged Pipe Fittings

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Stainless Steel Forged Pipe Fittings

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Stainless Steel Forged Pipe Fittings

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

- All goods are packed in wooden cases or pallets.

Suppliers of Stainless Steel Forged Pipe Fittings in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Export Sales of Stainless Steel Forged Pipe Fittings

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu