Metallica is one of the biggest suppliers of alloy steel in India, with over 3000 tons of stock in Mumbai, Maharashtra India. We sell our alloy steel products throughout India, and to international clients. Metallica also stocks and suppliers a wide range of stock of alloy steel pipes, alloy steel pipe fittings, alloy steel flanges and valves, and all our products are supplied with complete product certification. All our alloy steel products are sourced from domestic mills or are imported from reputed mills across the globe and stocked in India. Metallica may not be the biggest manufacturer of alloy steel products, but we are the biggest seller of seamless steel pipes in India. Be it carbon steel seamless pipes, alloy steel seamless pipes or stainless steel seamless pipes, we hold extensive stock to give our customers same day deliveries. ASTM A335, ASTM A333 and ASTM A213 are the most widely used standards according to which alloy steel seamless pipes are manufactured across the globe. Advanced production equipment, scientific and standardized management, strict quality assurance system and high-quality core team are the core competitiveness of the company. If you are interested in our products, please feel free to contact us. Best price with high quality products guaranteed!

What is an Alloy Steel?

Alloy steels contain alloying elements (e.g. manganese, silicon, nickel, titanium, copper, chromium, and aluminum) in varying proportions in order to manipulate the steel’s properties, such as its hardenability, corrosion resistance, strength, formability, weldability or ductility. The difference is somewhat uniform, but to make it distinguishable, all steel alloyed with higher than 8% of its weight of elements other than carbon and alloy is considered high-alloy steel. Alloyed steels are harder, more durable and more resistant to corrosion. Alloy steels with carbon levels of medium to elevated rates are difficult to weld. However, if the carbon levels are reduced to 1% to 3%, such alloy metals can achieve greater formability and weldability, thus, improved strength.

Applications of Alloy Steel

Alloy steel seamless pipes are widely used for low and medium pressure fluid transportation pipeline, casing tube, boiler pipe, petroleum and natural gas industry, chemistry industry, power generation industry, transformers, agriculture, bearings, general engineering, automotive, hydraulics, railway, mining, construction, aerospace, medical, defense and electric motors. Alloy steels grade P91 is mainly used for power industry. For welded construction, the ASME Boiler and Pressure Vessel Code limits the carbon content to less than 0.35%. Alloy steel is ideally suited for applications that require higher strength, improved toughness or better wear resistance than standard carbon steel grades. Alloy Steels are used in boiler construction because they are inexpensive, readily available, easily formed and welded to the desired shape and, within the broad limits, are oxidation- and corrosion-resistant enough to provide satisfactory service for many years to many industries. Alloy Steel is used across a range of highly demanding applications within the aerospace and power (nuclear) industries. Alloy Steel is also found in applications where its response to magnetism is important, in transformers and electric motors for example.

Properties of Alloy Steel

It is the addition of other elements that makes Alloy Steel extra strong. The elements (such as silicon and manganese) through heat treatment makes Alloy Steel with improved characteristics and additional benefits, such as increased corrosion resistance or improved weldability. The mechanical properties achievable are dependent on the addition of elements such as nickel, chromium, molybdenum and vanadium. The following is a range of improved properties in alloy steels (as compared to carbon steels): strength, hardness, toughness, wears resistance, corrosion resistance, hardenability, and hot hardness. To achieve some of these improved properties the metal may require heat treating. HSLA stands for high-strength low-alloy steel.

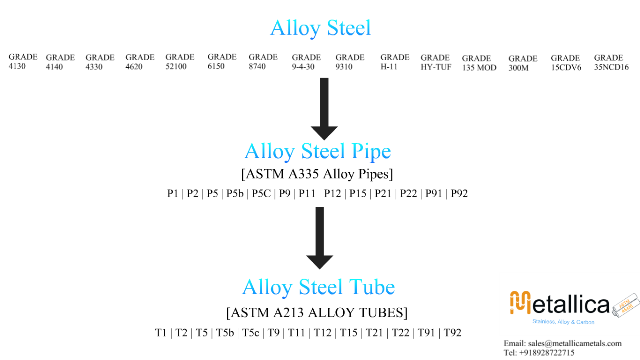

Types of Alloy Steel

There are 2 major types of alloy steel.

High-Alloy Steel: –

High-alloy steels are defined by a high percentage of alloying elements. The most common high-alloy steel is stainless steel, which contains at least 12 percent chromium. Stainless steel is generally split into three basic types: martensitic, ferritic, and austenitic. Martensitic steels contain the least amount of chromium, have a high hardenability, and are typically used for cutlery. Ferritic steels contain 12 to 27 percent chromium and are often used in automobiles and industrial equipment. Austenitic steels contain high levels of nickel, carbon, manganese, or nitrogen and are often used to store corrosive liquids and mining, chemical, or pharmacy equipment.

Low-Alloy Steel

Low-alloy steels have a much lower percentage of alloying elements, usually 1 to 5 percent. These steels have very different strengths and uses depending on the chosen alloy. Large diameter flanges manufacturers typically choose alloys for a specific mechanical property. The variety of potential alloys makes low-alloy steel useful for a variety of projects, including seamless rolled ring forging and studding outlet manufacturing.

While there are a lot of different alloying elements that can be used to improve the mechanical properties of steel, certain combinations are used often and there are different types of alloy steel that are more popular than others.

High strength low alloy (HSLA) steel is an alloy that provides greater atmospheric corrosion resistance and high strength. There are six different classifications of HSLA steel, with varying alloying elements used. Typically, vanadium, niobium, titanium, and copper are used to provide the increased strength, and copper, chromium, phosphorus, and silicon are used to increase corrosion resistance. Due to the high strength of HSLA steels, they can often be harder to form, in some cases calcium or zirconium are added to improve formability. Chrome moly is another common alloy steel. This material is an alloy of chromium and molybdenum, which improves hardenability, increase strength, high temperature resistance, corrosion, and oxidation resistance.

| ALLOY | SPECIFICATION | MAXIMUM USEFUL TEMPERATURE |

| Carbon-steel | SA178, SA192, | 850° |

| SA210, SA106, | ||

| SA515, SA516 | ||

| Carbon-1/2 | SA209 | 900° |

| Molybdenum | ||

| 1 1/4 Chromium- | SA213 T-11 | 1025° |

| 1/2 Molybdenum | SA335 P-11 | |

| 2 1/4 Chromium- | SA213 T-22 | 1075° |

| 1 Molybdenum | SA335 P-22 | |

| 18 Chromium- | SA213 TP304(H), | 1500° |

| 10 Nickel | 321(H), 347(H) |

Principle Effects of Major Alloying Elements On Alloy Steel

| Element | Percentage | Primary function |

| Aluminium | 0.95–1.30 | Alloying element in nitriding steels |

| Bismuth | – | Improves machinability |

| Boron | 0.001–0.003 | A powerful hardenability agent |

| Chromium | 0.5–2 | Increases hardenability |

| 4–18 | Increases corrosion resistance | |

| Copper | 0.1–0.4 | Corrosion resistance |

| Lead | – | Improved machinability |

| Manganese | 0.25–0.40 | Combines with sulphur and with phosphorus to reduce the brittleness. Also helps to remove excess oxygen from molten steel. |

| >1 | Increases hardenability by lowering transformation points and causing transformations to be sluggish | |

| Molybdenum | 0.2–5 | Stable carbides; inhibits grain growth. Increases the toughness of steel, thus making molybdenum a very valuable alloy metal for making the cutting parts of machine tools and also the turbine blades of turbojet engines. Also used in rocket motors. |

| Nickel | 2–5 | Toughener |

| 12–20 | Increases corrosion resistance | |

| Silicon | 0.2–0.7 | Increases strength |

| 2 | Spring steels | |

| Higher percentages | Improves magnetic properties | |

| Sulphur | 0.08–0.15 | Free-machining properties |

| Titanium | – | Fixes carbon in inert particles; reduces martensitic hardness in chromium steels |

| Tungsten | – | Also increases the melting point. |

| Vanadium | 0.15 | Stable carbides; increases strength while retaining ductility; promotes fine grain structure. Increases the toughness at high temperatures |

Comparision of Properties of Various Steel at Room Temperature

The table below shows the typical properties of steels at room temperature (25°C). The wide ranges of tensile strength, yield strength, and hardness are largely due to different heat treatment conditions.

Properties of Steel at Room Temperature

Leave A Comment